Company History

SPIRIT WITH STYLE®

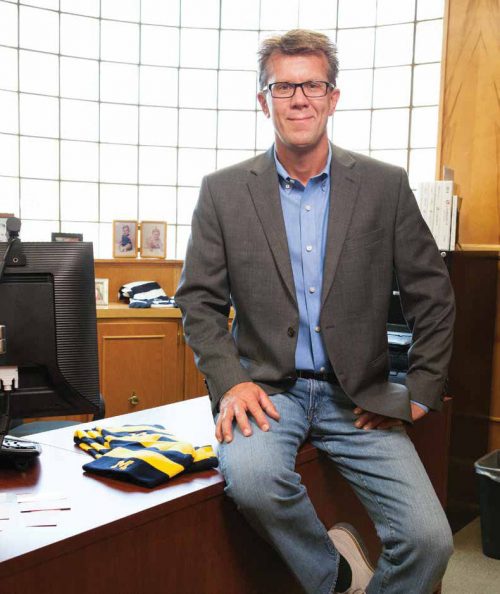

How Jon Kraut built LogoFit® with niche products, innovative processes and focused people.

By Brooke N. Bates

Jon Kraut was working his way through college, living a low-maintenance life in a friend’s basement, when he popped the question. With no experience whatsoever in the industry, he asked his father for $35,000 to launch his screen-printing business, LogoFit.

Kraut began crafting his business plan after hearing a friend vent about the lack of reliable screen printers to which he could refer customers of his small print shop. Kraut calculated how many shirts he would need to print to make $1 million in revenue his first year, then he made the case to his father, Dave, to launch the company.

“Looking back, it sounds crazy. Who borrows that much money without even knowing how to operate the equipment?” says Kraut, who was 23 when he opened the business in 1992. “But my father — to his credit — didn’t laugh. He loaned me the money, and we printed our first job in the factory the day we bought the press.”

As the sole employee, Kraut answered phones, printed shirts and delivered orders. Despite his hard work, he didn’t make $1 million the first year. But after eight months, he did have enough work from his friend’s referrals to hire his first employee: his mother.

“When parents work for their son, it’s quite an interesting dynamic,” Kraut says. “It can be both a blast and horrific. On her second day, while trying to mix ink with an electric drill, my mom sprayed ink over $1,500 worth of sweatshirts because she didn’t realize she had to hold on to the tub of ink.”

Kraut’s parents, step-parents and three brothers all worked with him at his business at some point — and he’s still close with all of them. He kept hiring, beyond family, as LogoFit grew slowly, sustained by contract screen-printing.

Looking to grow into new markets, Kraut moved LogoFit into a small retail location and started working directly with local schools and small businesses, focusing on screen-printed clothing, promotional products and signs. Then he met a large wholesale customer in the licensed collegiate business. He struck up a partnership in 1997, then acquired the company — launching LogoFit into higher education.

“We focused like a laser on being the best wholesale supplier to the college market,” Kraut says. “We narrowed our product offering to just a few styles that other vendors weren’t focused on and set out to be the best supplier of those products.”

“How can you expect to meet your goal if you don’t share metrics and successes with the people who make it happen?”

– JON KRAUT, GENERAL MANAGER, LOGOFIT

Today, LogoFit is licensed to manufacture products for 550 colleges and universities. With 95 percent of its sales to the college bookstore industry, LogoFit supplies more than 100 styles of logoed knit beanies, scarves, gloves, straws and other accessories to more than 4,000 retailers in all 50 states, plus Canada — including Barnes & Noble, Fanatics.com, Follett Higher Education Group, Rally House, Nebraska Book Co. and 1,500 independent retailers.

LogoFit has averaged 20 percent annual growth over the last six years, growing 38 percent in 2014, all while maintaining margins. Differentiating itself through niche products and proprietary processes, Kraut keeps the company focused on serving customers better, faster and more efficiently, boasting the largest selection of unique products, at the lowest minimums, with the fastest delivery.

STANDING OUT IN THE CROWD

Working with colleges is a seasonal business, which can present financial challenges.

“We’re a seasonal supplier, with huge discrepancies in our income month to month,” Kraut says. “Without a strong banking relationship, we would not have been able to grow as quickly as we have. The employees at FirstMerit Bank have consistently taken time to understand our business and its unique challenges to give us the liquidity we need.”

In serving the college bookstore industry, LogoFit faces significantly larger competitors, such as Nike, Under Armour and Adidas. The primary product of every competitor is baseball caps — so LogoFit doesn’t offer them. Instead, it focuses on unique, hard-to-find items, using a manufacturing process and a delivery model that stand out in the industry.

“Almost all of our competitors produce logoed products overseas,” Kraut says. “They import navy beanies with the University of Michigan “M” sewn on, so those are committed products they can only sell to one school. They need to book 72 or 144 logoed pieces of that style to make that viable.”

LogoFit has its products manufactured overseas to its specs, using a detailed corporate responsibility program to maintain high-quality standards through random third-party plant inspections. But its logo embellishments happen domestically in Flint.

“We import blank navy beanies, so we can sell that same beanie to 40 different schools,” Kraut says. “Our embellishment method allows us to produce very small minimums across a range of products, so we can make as few as six of one style quickly and efficiently, and ship them within 24 hours.”

Other small domestic embroiderers and screen-printers require 48- or 72-piece minimums due to the difficult process of machine changeover between styles. LogoFit struggled with similar issues — until seven years ago, when it engineered custom machines to utilize a sonic welding technology that revolutionized its production process.

“I’ll never forget when we brought this process online,” Kraut says. “I was literally jumping up and down in the conference room, throwing samples on the table, yelling, ‘This is a game-changer!’”

NEED FOR SPEED

LogoFit’s customized embellishment method, SonicWeld™, condensed the production cycle from four weeks to one. With that crunch came problems, as orders moved too quickly to keep up with manually.

Back then, LogoFit used physical job tickets to move orders from the art department to production to packaging, without centrally coordinating all the moving pieces. When colleges called to put a rush on their order, customer service reps had to search the production area to find the ticket and manually change the shipping date.

After the second season of SonicWeld™ chaos, Kraut took every employee to lunch to learn about the struggles and discuss improvements. With their feedback, he developed a robust software system to efficiently manage orders. The “Priority Order Control System” gives everyone real-time information to coordinate production. With the click of a mouse — and the understanding of production processes and capacities — customer service reps can change shipping dates instantly while customers are on the phone, and broadcast the change immediately.

With this flexibility, LogoFit reacts quickly to changes. To exploit that speed, dedicated customer service reps correlate national weather data with college football schedules and rankings to produce weekly reports to retail partners. Equipped with those reports, sales reps ask if they need to reorder gloves, scarves or knit headwear for that weekend’s chilly home game. Domestically logoed products can be replenished — at low minimums, within a day or two — using LogoFit’s LightSpeed™ delivery system.

“We’re the only company that can shoot that fast,” Kraut says. “In the licensing world, you’ve really got to stand out. If you don’t, it’s easy to get cut.”

To deliver on these promises to customers, Kraut relies on his team of 30+ employees, many of whom have been with him 10 years or more. He keeps turnover low by communicating transparently. Every week, he meets with supervisors to share financial data, dissecting P&Ls to compare sales, shipments, pending orders and other metrics to previous periods. Managers trickle this information down to employees at weekly production meetings and also meet with their reports during quarterly one-on-ones to set individual goals. All full-time employees participate in a tiered profit-sharing plan to share in the company’s wins.

“We share information with our employees because it allows us all to focus on the goal of profitability,” Kraut says. “I don’t know why more owners don’t do this. How can you expect to meet your goal if you don’t share metrics and successes with the people who make it happen? Because we share with our employees, they’re committed to helping us hit our goals.”

Contact LogoFit: (800) 778-8948 or LogoFit.com